Key Things To Know About Hydraulic Cylinder Repair

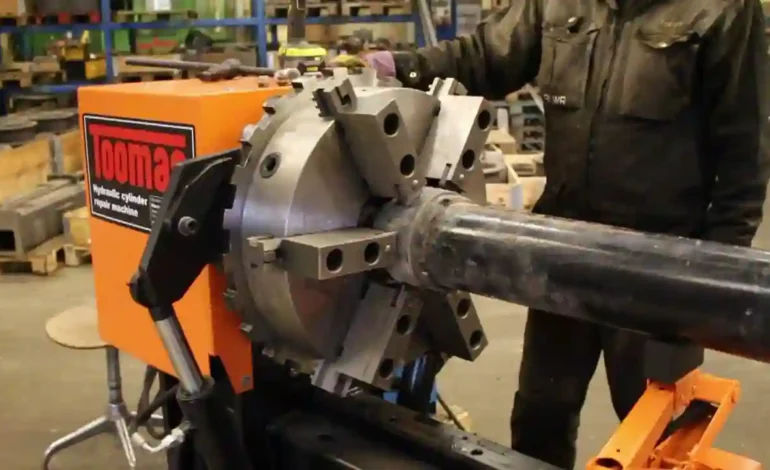

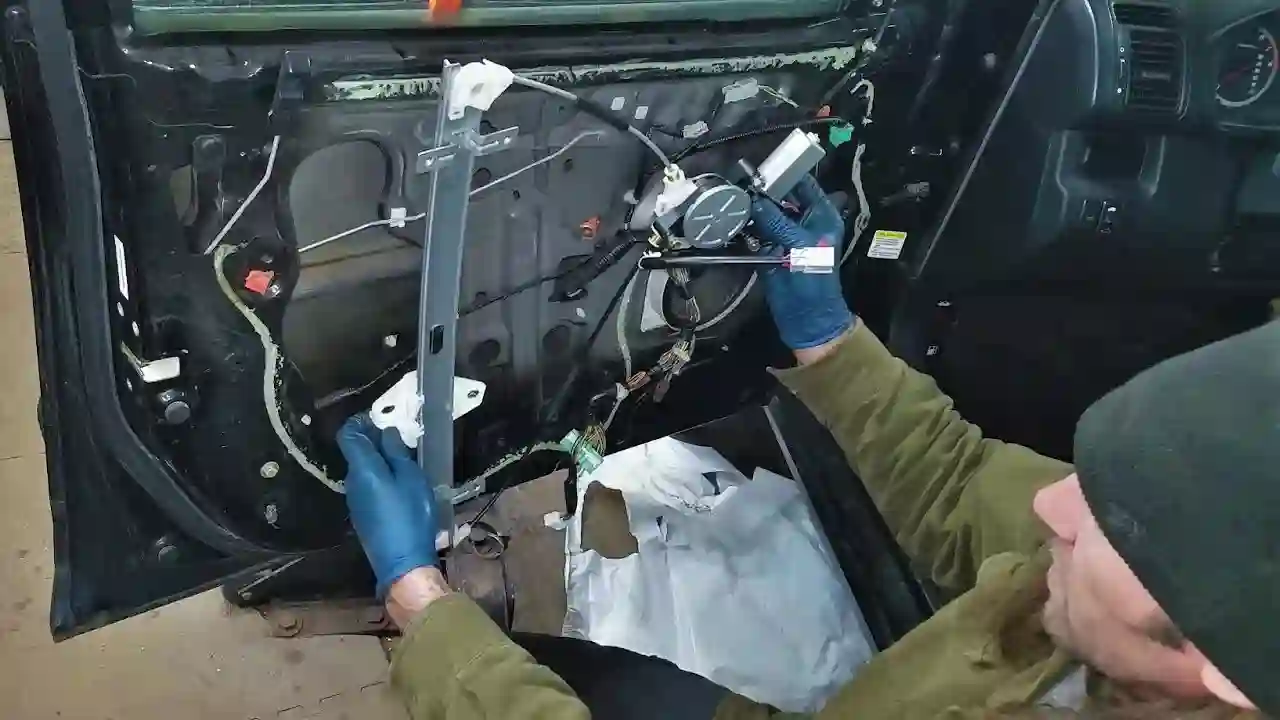

If your hydraulic cylinder develops an issue, you should never try to repair it yourself. This is because the consequence of a poor repair could be worse than the initial cause of the issue with the hydraulic cylinder. Also, this can cause the hydraulic cylinder to fail while in use, resulting in severe injury from disassembly.

For instance, if you try to uncouple a single-acting hollow cylinder, you’ll need to be vigilant for the force from the compressed spring so that it doesn’t fire the stop-ring directly into your face. If this happens, you could be subject to a severe or fatal injury that could cause you more. The best thing is to contact the repair to a professional or hydraulic cylinder repair contractor.

During the manufacture of these cylinders, manufacturers always try to ensure that their cylinders fit and are robust. However, they are still prone to develop certain issues, and when this happens, there’ll be a need to perform a repair on them.

Causes of Cylinder Wear and Damage

There are many reasons why a cylinder would wear or damage, but they are mostly a result of incorrect usage, which is mostly a result of poor knowledge of the operators.

Sideload

One of the largest enemies of your cylinder is the sideload, and many operators usually don’t know that this is an issue to keep an eye on. Sometimes these operators are usually not aware of the presence of sideload during application.

The issue of sideload usually causes improper contact between the load and the saddle. You can use a tilting saddle to improve the contact and enhance the functioning of the cylinder. Another thing worth noting is that for multiple-point lifts, the side loads can be a result of the hyperstatic nature of the lift.

Oil Contamination

Another thing that could cause cylinder damage is oil contamination. It’s important to ensure that the connections are kept clean. Also, the different couplers would need to stay spotless to ensure that debris does not accumulate in the hydraulic circuit. This is also a way that you can increase the life of your cylinder and pump.

Overload

Overload is also a common cause of damage, which is why it’s important to ensure that you know the weight limit of the cylinder. That way, you will be sure that you won’t overload the cylinder when lifting. While it’s important to maintain optimal load, it’s also worth mentioning that lowering the load that you use on the cylinder can result in uncontrollable movements, and this is mostly via the valve closing and opening.

With this, the load tends to rest on top of a few cylinders and eventually overloading them, which is equally what you want to avoid. You can avoid all of these problems by getting cylinders that come with controlled lifting pumps and EVO systems. With that, you can be sure that the cylinders will have full control of multi-point lifting, and this will equally reduce all the risks associated with an overloaded cylinder.

These are the main causes of hydraulic cylinder damage. It’s also worth noting that each of these causes yields different types of damage. However, one of the first steps toward repairing any of the type of damage is by identifying the root cause before coming up with a strategy to repair the cylinders. For emphasis, the potential causes of hydraulic cylinder damage are sideload, oil contamination, and overload. Also, it’s advisable to always contract your repairs to a trained professional or hydraulic cylinder repair contractor rather than opting to do the job all by yourself.